Protecting Underground Infrastructure: Safe and Efficient Pipe Replacement Techniques

Key Takeaways

- Effective underground pipe replacement strategies protect communities from costly leaks and infrastructure failures.

- Trenchless technology has revolutionized the industry, offering substantial savings in time, money, and environmental impact.

- Prioritizing safety, appropriate equipment, and well-defined processes is critical for minimizing risk and disruption.

- Continuous innovation is transforming how professionals replace and maintain subterranean pipelines.

Why Old Pipes Pose a Modern Problem

Underground networks of pipes in urban, suburban, and rural areas carry essential utilities like water and gas. Often made of outdated materials, these pipes are prone to cracks, leaks, or bursts due to natural ground movement, corrosion, and material fatigue. When a pipe fails, it often disrupts entire neighborhoods, strains municipal budgets, and property owners may face damaged basements or lawns.

With such stakes, utility professionals know that any replacement method must safeguard people and the infrastructure. Forward-thinking teams are now updating older replacement approaches and utilizing specialized solutions such as KOBUS PIPE PULLER CABLES to expedite trenchless replacement. This cutting-edge technology is designed to extract and replace aged service pipes efficiently, dramatically reducing the size of required excavations and the time needed onsite. Ongoing investments in infrastructure renewal will prevent waste and preserve water quality nationwide. A single break can lose millions of gallons of water, making proactive upgrades essential.

Traditional vs. Trenchless: Comparing Replacement Methods

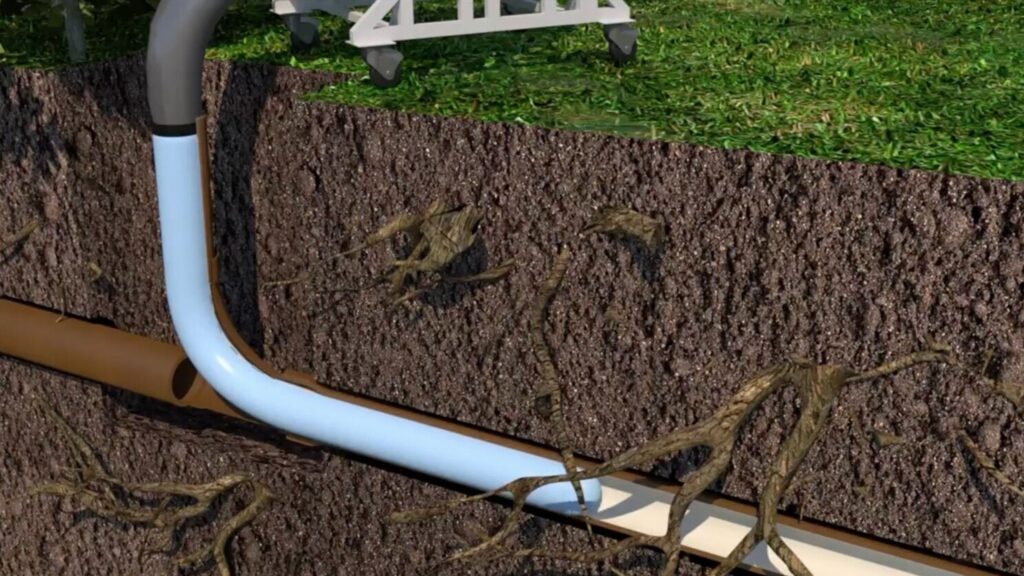

Traditional open-trench pipe replacement is inconvenient and noisy. At the same time, trenchless technology, which involves digging two small access pits at either end, minimizes surface impact, shortens project timelines, and delivers durable results. This method is preferred in urban environments or areas with elaborate landscaping, as it reduces public disturbance, generates goodwill, and saves municipalities money by limiting post-project repairs. Trenchless methods are becoming more popular due to their durability and cost-effectiveness.

Understanding Trenchless Pipe Pulling

Pipe pulling is a trenchless method for replacing problematic service lines in homes or businesses. It involves threading a high-strength cable through the existing pipe and attaching one side to the new one while applying pulling force. The new pipe follows the old path, which can be fragmented, removed, or left in place. This technique works even in restricted underground spaces and can be completed within a single workday, reducing inconvenience for residents and business owners.

Prioritizing Safety During Pipe Replacement

Underground utility work is a complex process that requires careful planning and safety measures. Hidden hazards like power lines, gas mains, aging water pipes, and shifting soils can introduce risks. Accurate locating and marking underground services using electronic locators, ground-penetrating radar, and updated maps is crucial. Supervisors require daily safety briefings and effective communication, including personal protective equipment (PPE), to ensure a smooth project. Two-way radios, hand signals, and mobile apps can help coordinate movements, especially when multiple utilities are nearby.

Environmental Benefits of Minimal Excavation

Trenchless replacements preserve local ecosystems by reducing surface disruption and preserving topsoil, compact roots, and wildlife. Trees, which rely on shallow roots, are less likely to suffer shock or death. Soil structure stays healthier, ensuring faster regeneration and avoiding erosion. Faster work and fewer hauls to and from the site result in lower emissions from equipment and work vehicles. This benefits city dwellers, reducing airborne dust and detours, and infrastructure owners, ensuring less long-term liability and community opposition, especially as cities strive for sustainability goals.

Choosing the Right Equipment for Each Job

Replacement jobs present unique challenges, such as tight rights-of-way, dense soils, odd pipe sizes, and underground obstructions. Selecting the right equipment for pipe pulling, cable tension, and soil remediation is a science and an art. Crews may conduct site assessments, deploy soil probes, or consult manufacturers to determine the machine or cable configuration. Staying current with industry trends, attending seminars, and collaborating with technical advisors helps avoid common pitfalls. Modern projects often use real-time performance monitoring, GPS positioning, and remote troubleshooting. Choosing proven solutions ensures efficient execution and high-quality finished infrastructure, protecting community investment.

Advancements and Future Directions in Pipe Replacement

Rapid technological advancements and increasing regulatory scrutiny mark the future of underground pipe replacement. Smart sensors in new pipes can monitor temperature, pressure, and flow in real-time, providing early warnings for leaks or structural weaknesses. Digital project management platforms streamline communication and planning. Investing in next-generation pipe materials, cable systems, and monitoring solutions is an intelligent long-term decision requiring responsible stewardship and innovation for reliable water, gas, and data flow.

Responses