Splicing Techniques: A Comprehensive Guide

Splicing, the process of linking two fiber optic cables together to form a single, uninterrupted cable, is essential in the field of fiber optics. This method allows for the unhindered transmission of audio, video, and data over great distances. In the following paragraphs, splicing techniques, we will discuss the various splicing methods, their uses, and the criteria to be taken into account when selecting one.

Definition of Splicing

Splicing, at its most fundamental level, is the act of permanently uniting two fiber optic lines. The objective is to build a link with low loss, so optical signals experience minimum loss and reflection as they go through. Different splicing methods have their own advantages and disadvantages.

Importance of Splicing

For several reasons, splicing is an essential skill for anyone working with fiber optics. First, it facilitates the growth of optical fiber networks through the effortless joining of cables. In cases where running additional lines would be too expensive or inconvenient, this becomes crucial. Second, splicing provides for very dependable and performant connections, which are especially important in fields like healthcare, data centers, and telecommunications. Finally, splicing makes it possible to quickly and easily repair broken or malfunctioning fiber optic cables, thus minimizing service interruptions and maximizing uptime.

Types of Splicing

Mechanical Splicing

Aligning and linking fiber optic wires using mechanical connectors, or “splicing,” is a common technique. This method has a number of benefits, including its speed, simplicity, and potential for reuse. The insertion loss is greater than in fusion splicing, which is a disadvantage. To achieve ideal performance, mechanical splicing best practices call for meticulous fiber preparation, precise alignment, and exhaustive testing.

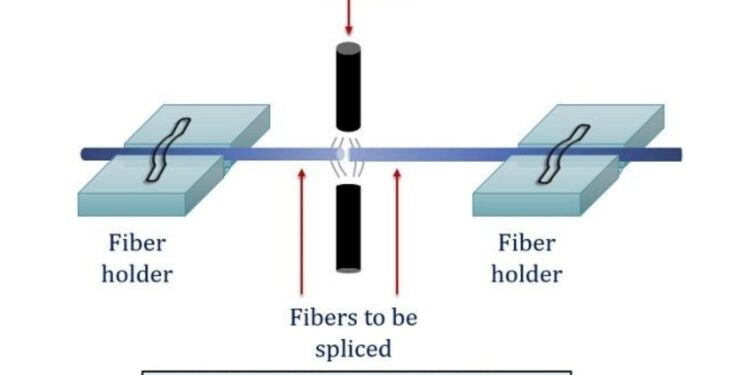

Fusion Splicing

The fiber ends are melted and fused together in a process known as fusion splicing, which is commonly used to permanently link fiber optic cables. This method has a very high degree of mechanical stability and a very low insertion loss. Fusion splicing is widely splicing techniques, employed in long-distance communication networks because it may be performed on both single-mode and multimode fibers. Because it is more suited to experienced installations, it takes specialized equipment and knowledge to conduct accurately.

Ribbon Splicing

Splicing numerous strands at once, as in ribbon cables, requires a specific method known as ribbon splicing. This approach facilitates a greater connection density, making it useful for applications that call for numerous fiber connections in a confined area. Ribbon splicing’s benefits include reduced wait times, higher output, and rock-solid dependability. However, specialized tools and knowledge may be needed.

Factors to Consider

There are a few things to keep in mind when deciding on the best splicing method:

Fiber Types:

Splicing methods for various fiber kinds vary. It is crucial that the splicing technique be appropriate for the fiber type being used.

Environment: It is important to assess the surrounding conditions in which the splicing will occur. Choice of splicing method is affected by environmental factors such as temperature, humidity, and chemical exposure.

Budget: Some splicing procedures require more expensive equipment or expertise than others, so the available money may play a role in the decision.

Future Flexibility: Think about the possibility of the fiber optic network requiring upgrades or alterations down the road. Time and materials can be conserved in the long term by selecting a splicing method that permits simple rework or extra splices.

Step-by-Step Splicing

Let’s break down the splicing operation into its component parts so you can grasp it completely:

Preparation: First, make sure the fiber optic wires are spotless and ready to go. Remove the coating and sanitize the fiber ends.

Fiber Cleaving: In order to get a splice with minimal loss, the fiber ends must be flattened and smoothed with a precision cleaver.

Cleaning: Use lint-free wipes and isopropyl alcohol to completely disinfect the fiber ends.

Splicing: Align the fiber end preparations and splice them together via mechanical, fusion, or ribbon splicing.

Testing: Measure both the insertion loss and the return loss to ensure a high-quality splice. That way, you know the spliced connection is solid and unbreakable.

Common Splicing Mistakes

Splicing may seem simple, but it’s easy to make mistakes that compromise the connection’s quality and performance. Common blunders include a lack of suitable fiber preparation, alignment, cleaving, or fusion, or subpar mechanical connections. Avoiding these blunders and achieving the best possible splicing results can be accomplished through taking the time to study best procedures, following product guidelines, splicing techniques, and getting professional training.

Maintenance and Repair

Damage, degradation, or a shift in bandwidth demands over time could necessitate servicing or replacement of an existing fiber optic cable. By isolating the damaged portions and creating new splices, splicing facilitates efficient repair. The lifetime and dependability of the fiber optic network can be ensured through routine maintenance including inspections, cleaning, and prompt repairs.

Future of Splicing

Splicing is an area that is rapidly developing alongside technological progress. Better splicing tools, quicker fusion splicing methods, and automated ribbon splicing are just a few examples of the innovations that are continually being developed. Faster and more effective development of fiber optic networks is possible with the promise of better connection density, enhanced dependability, and improved ease of use in the future of splicing.

Conclusion

In conclusion, splicing techniques are crucial in the fiber optics industry because they enable robust and high-performance connections. Professionals can make better decisions about the deployment and maintenance of fiber optic networks if they are familiar with the various splicing methods, their benefits and drawbacks, and best practices. The best performance and connectivity can be achieved through mechanical splicing, fusion splicing, or ribbon splicing if the components are properly prepared, aligned, and tested.

Responses